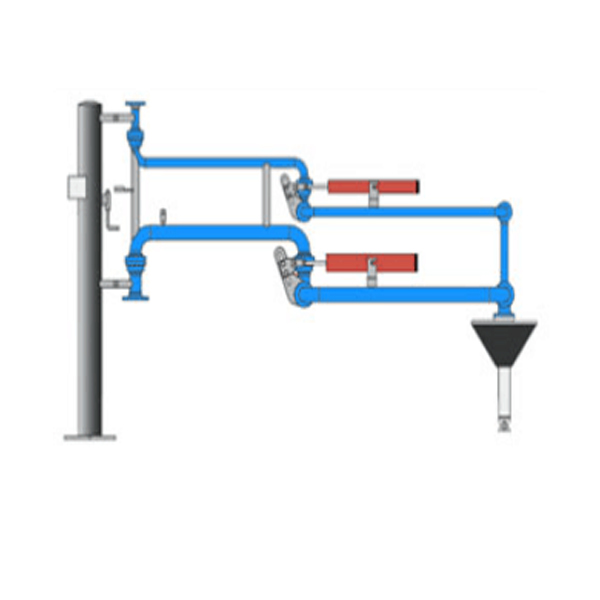

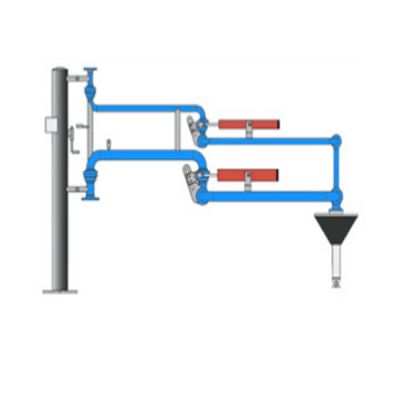

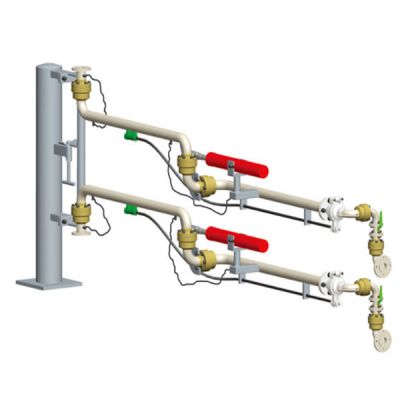

This equipment is suitable for the top loading of trucks and trains with volatile and toxic media such as light oil, methanol and benzene, and can recover the volatile media. The gas phase tube can be full hose, half hose or full hard tube. The loading arm is mainly composed of fixing, rotating, operating, balancing and other mechanisms and oil pipes.

AL1412 recovery gasoline loading arm is suitable for the top loading of cars and trains with volatile and toxic media such as light oil, methanol and benzene, and can recover volatile media. The gas phase tube can be full hose, half hose or full hard tube. The truck tube is mainly composed of fixing, rotating, operating, balancing and other mechanisms and oil pipes. Among them, the slewing mechanism (swivel joint) is carefully made of forged steel or aluminum alloy, with double row ball bearings inside and special stainless steel sealing rings. It has the advantages of flexible rotation, reliable sealing performance, and durability. The balance system includes counterweight, torsion spring, compression spring, extension spring and lead screw, as well as hydraulic and pneumatic balance, all of which can be operated with very little force.

The loading arm is a special equipment in the process of fluid loading and unloading in the petrochemical industry, also known as the fluid loading and unloading arm. It uses a rotary joint to connect rigid pipes and elbows to realize the movable equipment for transporting liquid media between trains, car tankers and trestle storage and transportation pipelines, replacing the old-fashioned hose connections. It has high safety and flexibility. properties and long lifespan.